If the vast industrial piping network is the "vascular system" of modern civilization, then valves are undoubtedly the "heart valves" and "gatekeepers" controlling this circulatory pulse.

From deep-sea oil extraction rigs to precision pharmaceutical laboratories, these seemingly ordinary mechanical "switches" determine the safety, efficiency, and stability of entire systems. This article provides a deep-dive analysis into the mechanical structures, working principles, and selection logic of the 8 most universal industrial valves.

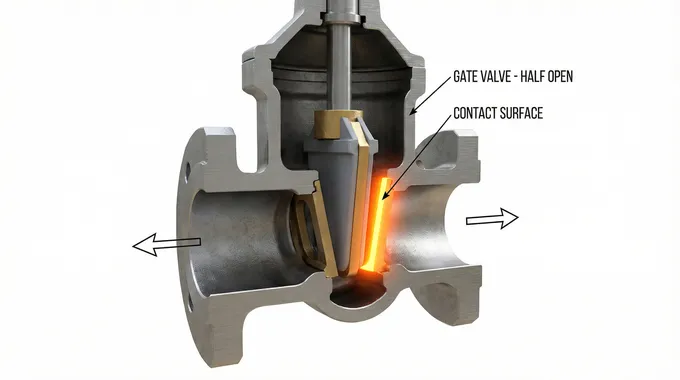

01 Gate Valve: The Stalwart Isolationist

Structural Characteristics

The Gate Valve is the workhorse of the piping world. Its defining feature is the closure member—the gate (or wedge)—which moves in a direction strictly perpendicular to the fluid flow.

Design Philosophy: The internal flow path is typically "straight-through." When fully open, the gate retracts completely into the bonnet, leaving the flow passage virtually unobstructed. This results in minimal pressure drop and a flow coefficient ($C_v$) almost identical to a pipe of the same length.

Core Components: The assembly consists of the valve body, a wedge-shaped or parallel gate, seats, and an actuation stem. The stem can be Rising (providing visual indication of position) or Non-Rising (ideal for confined spaces like underground municipal water systems).

Working Principle

The operation relies on a threaded stem to lift or lower the gate.

Opening: As the stem rotates, the gate is lifted into the bonnet recess, allowing laminar flow.

Closing: The gate descends to wedge between the seats, creating a tight seal against fluid pressure.

CRITICAL WARNING: |

Application Fields

Due to their ability to cut through thick fluids and provide minimal flow resistance, Gate Valves are the primary choice for systems that do not require frequent cycling:

Municipal Infrastructure: Main water supply and sewage lines.

Fire Protection: Systems where full flow is critical during emergencies.

Heavy Industry: Large-bore pipelines in oil refineries and chemical plants for isolation purposes.

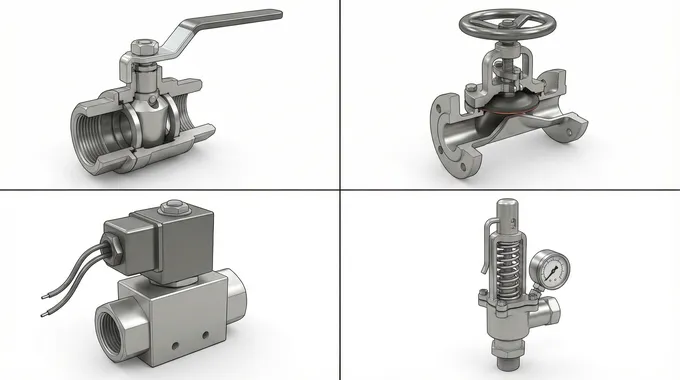

02 Globe Valve: The Precision Throttler

The "S-Shape" Flow Master

Unlike the straight path of a gate valve, the Globe Valve forces the fluid to change direction. Its signature feature is the tortuous "S-shaped" or Z-shaped internal flow path. The closure member is a plug or disc that moves parallel to the flow axis, plunging into the seat like a piston.

This structural design allows for a shorter stroke to reach full open/close status compared to gate valves, making it faster to operate and easier to maintain. However, the directional change comes at a cost: significantly higher head loss (fluid resistance) and turbulence.

Working Principle & Installation

The valve stem moves the plug linearly. Because the disc moves against or with the flow stream, it offers superior control over the flow rate, making it the industry standard for regulation.

Installation Principle: "Low Inlet, High Outlet" |

Application Fields

Globe valves are indispensable where precise flow modulation is required:

Power Generation: Boiler bypass systems and steam vents.

Chemical Processing: Feed lines requiring variable flow rates.

Cooling Systems: Temperature control loops.

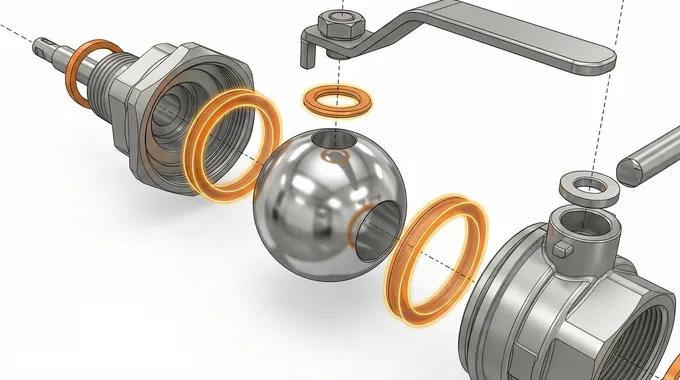

03 Ball Valve: The Quarter-Turn Speedster

90-Degree Rapid Action

The Ball Valve represents a leap in valve evolution, prioritizing speed and tightness. The closure element is a polished sphere with a central bore (hole).

Mechanism: Rotating the valve stem by merely 90 degrees (1/4 turn) aligns the bore with the pipeline (open) or positions the solid face against the flow (closed).

Sealing Technology: Modern ball valves utilize "floating ball" or "trunnion mounted" designs. In a floating design, line pressure pushes the ball against the downstream soft seat (usually PTFE/Teflon) to create a bubble-tight seal.

Key Advantages

Speed: Instant shutoff capabilities make them ideal for emergency shutdown systems (ESD).

Minimal Resistance: Full-port ball valves offer zero flow restriction and are "piggable" (allowing cleaning devices to pass through).

Resilience: The wiping action of the ball against the seat makes them self-cleaning, handling dirty media, slurries, and high-viscosity fluids without jamming.

Application Fields

Oil & Gas: Long-distance natural gas pipelines (where low friction is paramount).

General Industry: Utility lines (air, water, gas).

High Viscosity: Handling syrups, heavy oils, or fluids with suspended particles.

04 Butterfly Valve: The Lightweight Champion

The Ruler of Large Diameters

When pipeline diameters exceed DN300 (12 inches), weight and space become critical constraints. The Butterfly Valve solves this with a wafer-thin profile. The closure element is a disc mounted on a rotating shaft in the center of the fluid stream.

Like the ball valve, it is a quarter-turn device. However, unlike the ball valve, the disc is always present in the flow stream, creating a slight pressure drop even when fully open.

Evolution of Technology

Concentric (Zero Offset): The rubber-lined standard version. Excellent for water but limited by temperature.

High-Performance (Double/Triple Offset): Modern engineering has introduced metal-seated, triple-eccentric butterfly valves. These use complex geometry to eliminate friction during rotation, allowing the valve to seal tightly even under extreme temperatures (up to 600°C) and high pressures.

Application Fields

HVAC: Heating and ventilation systems in skyscrapers.

Water Treatment: Large intake and outfall lines in purification plants.

Ventilation: Gas and air handling systems where space is at a premium.

Specialized Valves: The Specific Problem Solvers

While the "Big Four" above handle 80% of tasks, specialized scenarios require specialized architecture.

05 Plug Valve (The Robust Ancestor)

Structure: Features a cylindrical or conical plug with a bored passage. It is the historical predecessor to the ball valve.

Superpower: Multi-port Design. Ideally suited for diverting flow (3-way or 4-way configurations).

Application: Excellent in systems with suspended solids (slurries) or applications requiring extreme seal integrity, such as mining and oilfield extraction.

06 Diaphragm Valve (The Hygienic Standard)

Structure: A flexible membrane (diaphragm) is pressed down to close the flow. Crucially, this diaphragm isolates the operating mechanism from the fluid.

Superpower: Zero Contamination. There are no "dead legs" or crevices for bacteria to hide, and the mechanical parts never touch the fluid.

Application: The gold standard for Bio-Pharma, Semiconductor Ultra-Pure Water, and corrosive acid handling.

07 Solenoid Valve (The Automation Bridge)

Structure: An electromechanical device using a magnetic coil (solenoid) to move a plunger.

Superpower: Instant Response. Reaction times are measured in milliseconds. It bridges the gap between electronic control systems and physical fluid movement.

Application: Fluid power pneumatics, medical dialysis machines, and automated dosing systems.

08 Safety Valve (The Final Defense)

Structure: A normally closed valve kept shut by a calibrated spring or pilot mechanism.

Superpower: Passive Protection. It requires no external power. When system pressure exceeds a set limit, it automatically "pops" open to relieve pressure, preventing catastrophic explosions.

Application: Required by law on boilers, pressure vessels, and steam lines.

Conclusion: The Art of Selection

There is no such thing as a "perfect" valve in isolation—only the valve that is perfectly matched to its specific operating condition.

Need absolute isolation with low pressure loss? Choose a Gate Valve.

Need to regulate flow precisely? Choose a Globe Valve.

Need fast action and tight sealing? Choose a Ball Valve.

Dealing with a massive water pipe in a tight space? Choose a Butterfly Valve.

Understanding the "temperament" and mechanical DNA of these components is the first step in building a safe, efficient, and long-lasting industrial fluid system.