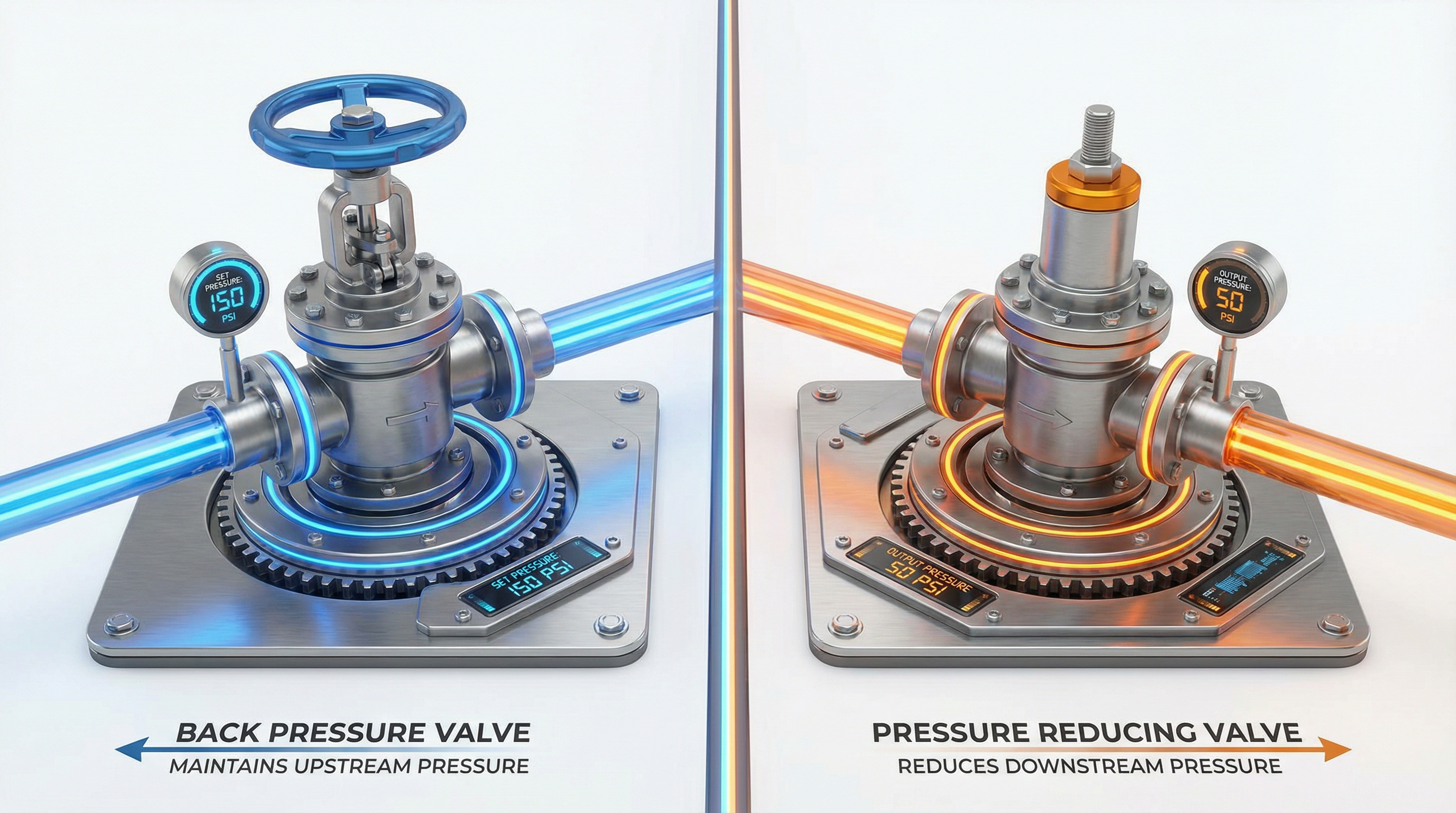

In the complex vascular system of modern industry, valves are the heart valves ensuring the "blood" flows correctly. Two components are frequently cited, often confused, but critically different: the Back Pressure Valve (BPV) and the Pressure Reducing Valve (PRV). They are the "Twin Stars" of pressure control, but mixing them up can lead to catastrophic failures. Who governs the upstream? Who protects the downstream? Let’s find out.

Section 1: Working Principles (The Dual Dynamics)

1.1 Back Pressure Valve (BPV): The "Resistance Generator"

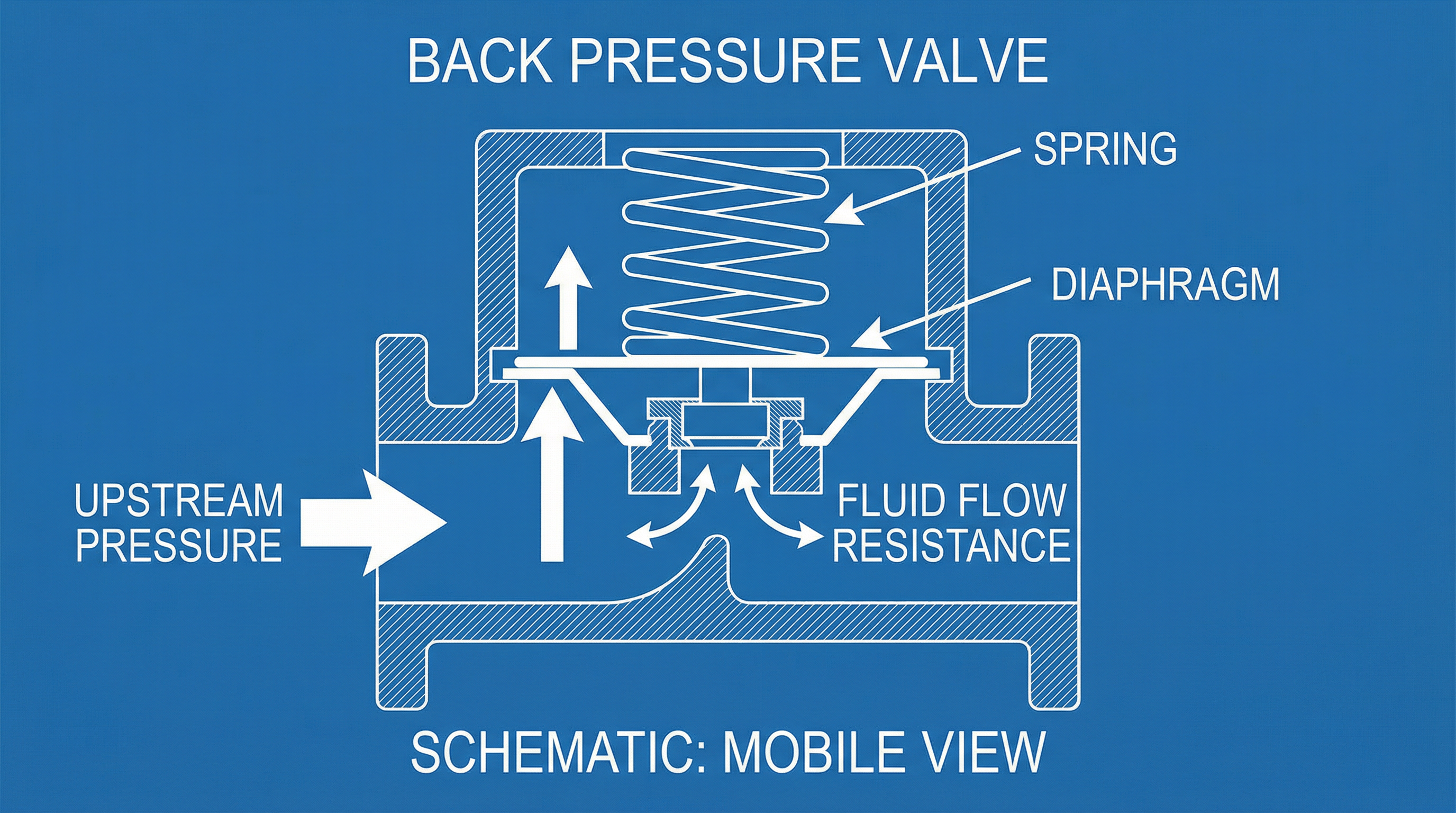

The Back Pressure Valve is essentially a guardian of the upstream pressure. Its philosophy is "Resistance for Maintenance." It operates on a force balance:

Pressure Sensing: When upstream pressure is below the set point, the spring pushes the diaphragm tight. The door is shut.

Release Mechanism: Once upstream pressure exceeds the set point, the fluid overcomes the spring, cracking open to bleed off excess fluid.

Anti-siphon: Acts as a check valve, preventing gravity drainage or the "siphon effect" when pumps stop.

1.2 Pressure Reducing Valve (PRV): The "Throttling Depressurizer"

The Pressure Reducing Valve protects the downstream. Its philosophy is "Throttling for Stability." It converts chaotic high-pressure input into consistent output.

Unlike the BPV, the PRV is constantly "listening" to the output side via a feedback loop. If the outlet pressure rises, the diaphragm pushes up, closing the valve plug to restrict flow, thus lowering the pressure back to equilibrium.

Section 2: Feature Face-off (Core Differences)

Engineers often ask, "Which one do I need?" Here is the definitive comparison card:

Primary Focus BPV: Upstream Pressure (Inlet) |

Action on Pressure Rise BPV: Opens to relieve excess |

Key Scenario BPV: Dosing pumps, Reactors |

3 Core Values of Back Pressure Valve (BPV)

System Stability: Prevents cavitation and actuator shudder.

Anti-Siphon Safety: Stops gravity-induced drainage in dosing loops.

Indirect Flow Control: Stabilizes flow variance by maintaining pump load.

4 Advantages of Pressure Reducing Valve (PRV)

Equipment Bodyguard: Protects downstream pipes from bursting.

Energy Efficiency: Reduces unnecessary high flow rates.

Micro-Precision: Keeps pressure fluctuations within ±0.001 MPa.

Cascaded Safety: Steps down pressure safely in stages.

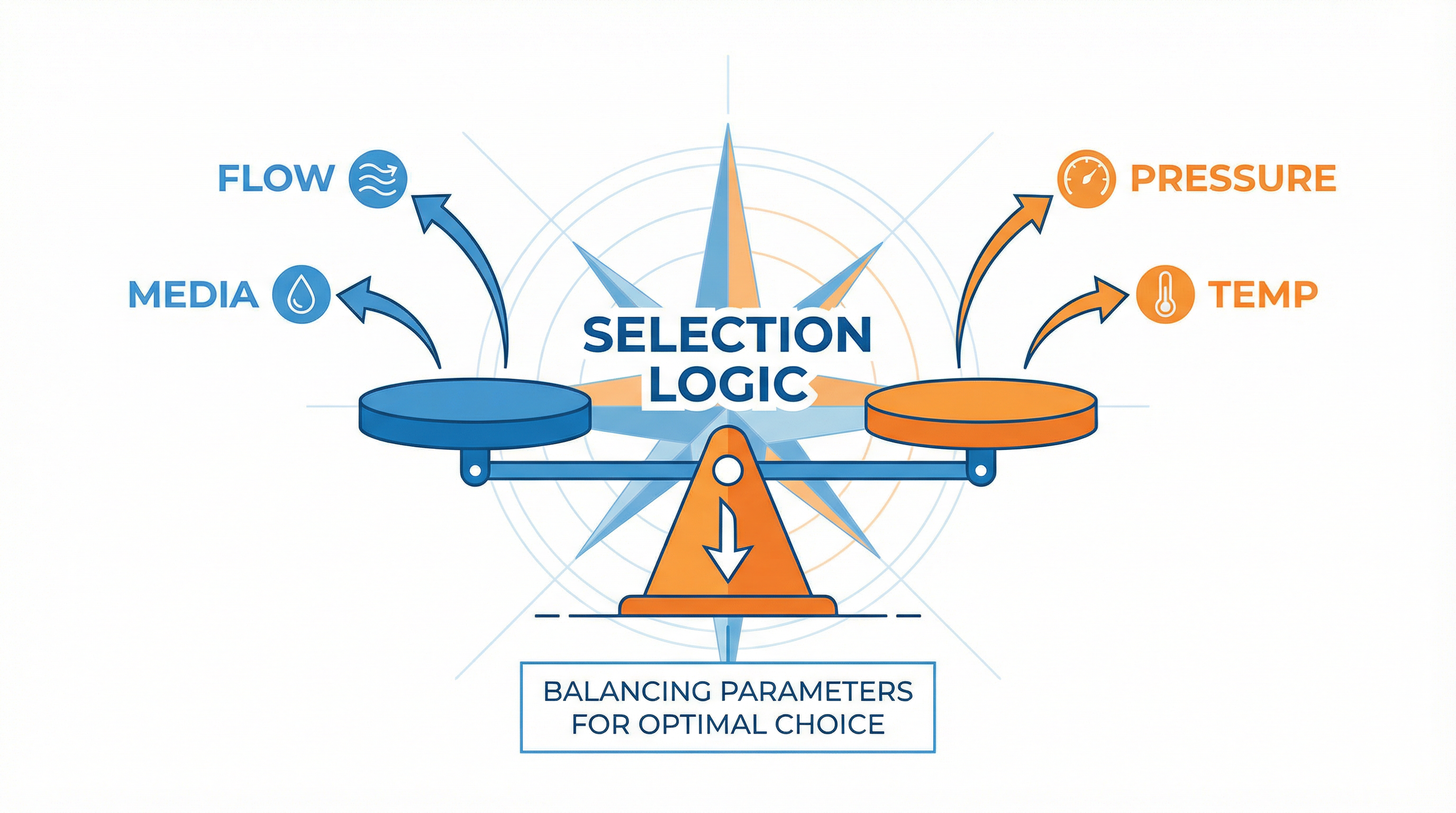

Section 3: Selection Logic (How to Choose)

Choosing the wrong valve is not just inefficient; it’s dangerous. Here is the selection logic used by top experts.

For Back Pressure Valves:

Pressure Range Match: It must handle the maximum possible system pressure (e.g., deep-sea rigs needing 15 MPa).

Chemical Compatibility: For corrosive media, stainless steel may fail. Use Hastelloy or PTFE-lined bodies.

Response Time: For high-speed dosing, diaphragm valves offer 60% faster response than piston types.

For Pressure Reducing Valves:

The Cv Value: Never size based on pipe size alone. Calculate Cv to avoid "hunting" and seat destruction.

Turn-Down Ratio: Ensure it handles both trickle flow and high demand (aim for a 10:1 ratio).

Sealing Class: For explosive gases like Hydrogen, "leak-tight" isn't enough—require ANSI Class VI shutoff.

Section 4: Real-world Applications & Future Trends

Case Study: The "Pressure Sandwich"

In a synthetic ammonia plant, these valves work as teammates. A PRV steps down inlet gas, a BPV holds reactor pressure, and another PRV stabilizes storage.

"This configuration increased synthesis efficiency by 15% and added 20,000 tons of annual yield." |

Future Trends: Intelligent Control

As Industry 4.0 arrives, the "dumb" mechanical valve is evolving into a smart device.

Digital Twins: Simulating valve behavior virtually to optimize settings before installation.

Predictive Health: Acoustic sensors detecting worn seats 30 days before failure.

Adaptive Algorithms: AI adjusting resistance in real-time for changing fluid viscosity.

Conclusion

The "King" of pressure control is not a specific valve, but the engineer who knows how to wield both. Choose wisely, control precisely.