In high-stakes industrial environments, confusing a needle valve with a metering valve isn't just a technical error—it's a costly mistake. While both manage flow, their core designs dictate vastly different applications, and choosing incorrectly can lead to system failure, product contamination, or significant financial loss.

1. Core Definitions: Identity & Mission

Sniper of Precision Flow: The Needle ValveA needle valve is designed for the precise regulation of flow rates in fluid or gas systems. Its mission is to grant operators fine-tuned control, acting like a sniper's scope for flow adjustment, but it is not primarily designed for a perfect, leak-proof shutoff. |

Guardian of Vacuum Pressure: The Metering ValveA metering valve is engineered for extremely fine flow adjustment, particularly in vacuum systems. Its primary directive is airtightness and repeatability. It serves as a guardian, meticulously controlling minute gas flows while maintaining system integrity without leaks. |

2. Structural DNA: The Mechanical Difference

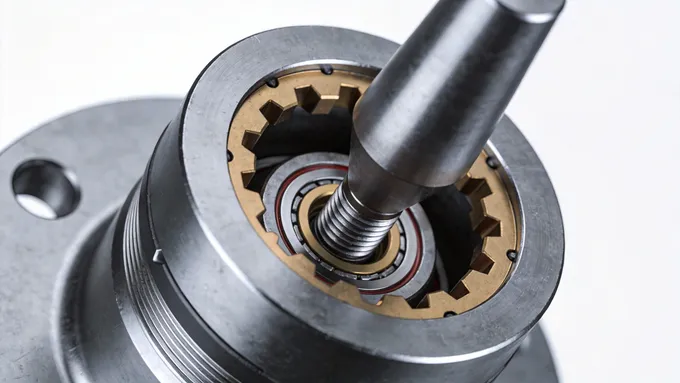

The needle valve features a long, tapered, cone-shaped pin (the "needle") that fits into a valve seat. As the handle is turned, the needle moves in or out, creating a variable annular space. The seal is typically a direct metal-to-metal contact, which offers good control but is not hermetically sealed.

Conversely, the metering valve is built for absolute sealing. It often employs an elastomer seal on the valve stem or seat and features extremely fine-pitch threads. This allows for many rotations of the handle to produce a very small, highly controllable change in the plunger's position, ensuring both micro-adjustments and a bubble-tight seal.

3. Mechanism & Applications

The tactile feedback from a high-quality metering valve is distinct. The high number of turns provides a sense of deliberate, incremental control, unlike the quicker action of a standard needle valve. This feedback is critical in sensitive operations where over-shooting a setpoint is not an option.

Typical Applications:

Needle Valve: General industrial applications like controlling water flow to turbines, regulating fuel in carburetors, or managing gas in processing plants where absolute shutoff is handled by another valve.

Metering Valve: High-purity gas delivery in semiconductor manufacturing, controlling gas mixtures in mass spectrometry, and regulating vacuum levels in laboratory research equipment.

Metering Valve: Precision control of medical gases in analytical instruments or regulating anesthesia flow, where accuracy and leak prevention are paramount.

4. Engineer's Selection Guide

If Pressure Regulation is key... | → Choose a Needle Valve. It excels at throttling flow under high pressure. |

If the medium is Vacuum or Gas... | → Choose a Metering Valve. Its airtight seal is non-negotiable for vacuum integrity. |

If Micro-Liter Precision is required... | → Choose a Metering Valve. The fine-pitch threading allows for unparalleled adjustment resolution. |

5. Real-world Case Study

Lesson Learned: Semiconductor ContaminationA semiconductor fabrication plant mistakenly used a standard needle valve to control the flow of a high-purity process gas into a deposition chamber. The valve's metal-to-metal seal, not designed for hermetic closure, allowed a minuscule amount of ambient air to leak into the system overnight. This atmospheric contamination ruined an entire batch of silicon wafers, resulting in a loss exceeding $100,000. A switch to a proper metering valve with an elastomer seal completely resolved the issue, highlighting how the "micro" difference in valve selection has macro-financial consequences. |

Understanding the distinct roles of needle and metering valves is fundamental to engineering excellence and operational success.