Internal leakage in pressure regulators is a silent profit killer. It's often overlooked during routine maintenance, yet it can lead to significant energy waste, production losses, and severe safety incidents. This analysis delves into its root causes and proposes a comprehensive prevention strategy.

Symptoms and Hazards of Internal Leakage

The primary symptom is a gradual increase in downstream pressure when the system is not consuming gas. This leads to direct financial losses. For instance, a medium-pressure steam system with a slight leak can waste over 50 tons of steam per hour. Annually, this equates to a staggering loss of approximately 1.92 million tons, representing a huge economic drain. More critically, uncontrolled pressure build-up can trigger safety valves, and in worst-case scenarios, cause downstream equipment to rupture, leading to catastrophic accidents.

Root Cause Analysis

1. Debris and Impurities

Welding slag, rust, and other particulate matter are the most common culprits. These impurities can get lodged between the valve plug and seat, preventing a tight seal and causing continuous leakage.

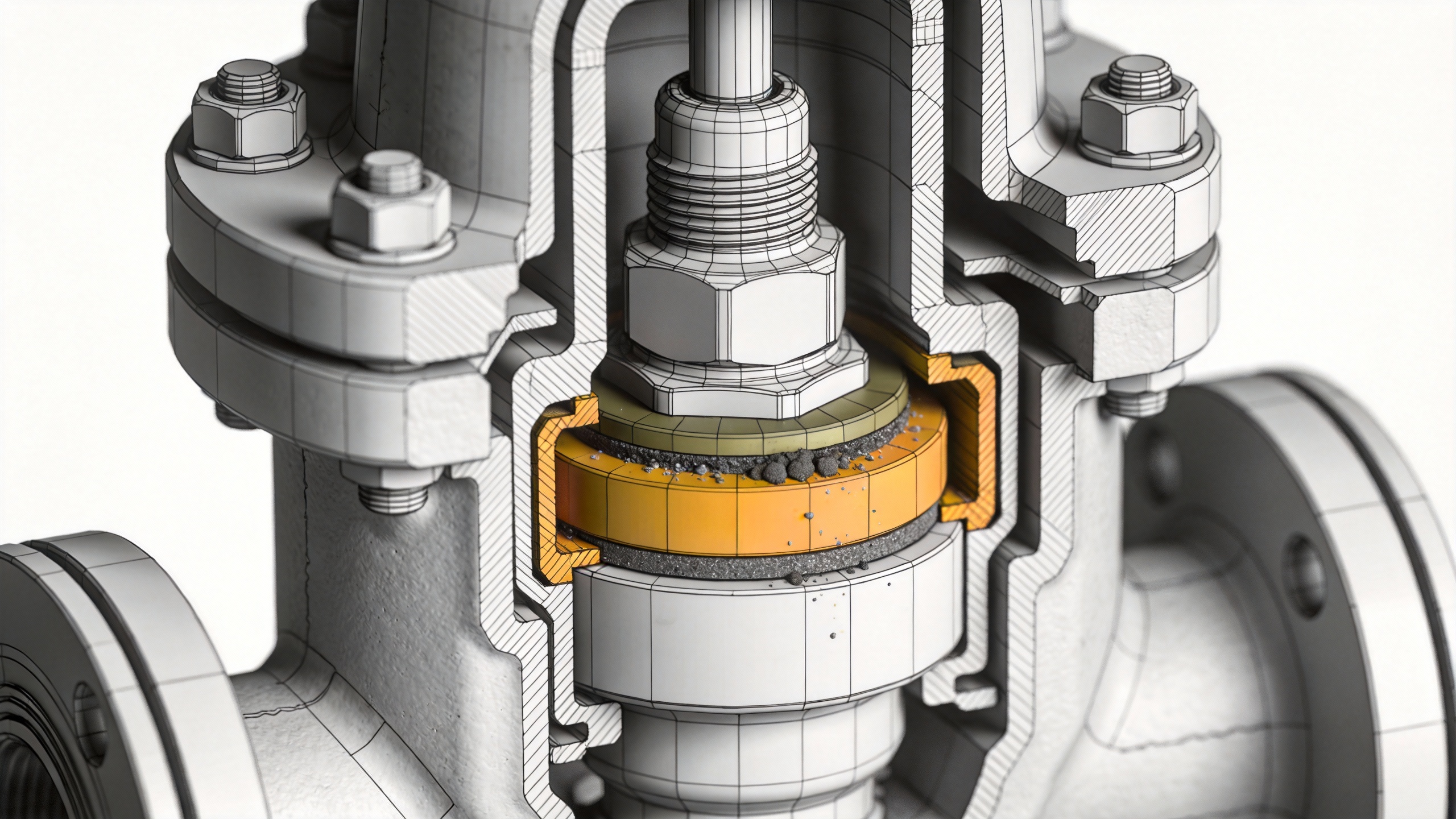

2. Component Wear and Corrosion

High-frequency operation and corrosive media can erode the sealing surfaces of the valve components. This degradation compromises the integrity of the seal, leading to persistent internal leaks.

Systemic Prevention and Solutions

1. Enhanced Filtration

Installing a high-quality filter upstream of the regulator is the most effective preventive measure. The filter's mesh size should be selected based on the specific media and operating conditions to effectively capture harmful particulates.

2. Proactive Maintenance

Regularly scheduled inspections and cleaning of the regulator's internal components are crucial. This includes disassembling the valve to check for wear, corrosion, and trapped debris, followed by thorough cleaning and reassembly.

Case Studies

Case Study 1: Petrochemical Plant

A major petrochemical facility experienced frequent tripping of its low-pressure steam safety valves. Investigation revealed that welding slag from initial construction had damaged the seats of multiple regulators. After implementing a protocol of installing Y-type filters and conducting a system-wide purge, the internal leakage issue was resolved, saving an estimated $200,000 annually in steam losses.

Case Study 2: Pharmaceutical Production

In a high-purity steam system for sterilization, inconsistent downstream pressure was compromising product quality. The cause was traced to fine particulate corrosion on the regulator's soft seat. Switching to a regulator with a more robust, corrosion-resistant alloy seat and upgrading the upstream filtration to a finer mesh stabilized the process and prevented costly batch failures.

Future Trends: Smart Monitoring

The future of prevention lies in IoT and smart technology. Pressure sensors integrated with diagnostic software can now monitor for subtle, creeping pressure increases in real-time. This allows for predictive maintenance alerts before a leak becomes significant, transforming system management from a reactive to a proactive model.