In the intricate vascular system of modern industry—from aerospace to semiconductor manufacturing—the humble ferrule fitting acts as the critical connection point. As the winds of "Domestic Substitution" blow across China's industrial sector, we explore the gap in technology, pricing, and the future of fluid control between domestic brands and global titans.

1. Technical Standards & Pressure Ratings

The defining characteristic of a high-quality fitting is its ability to withstand pressure without compromise. Here, the gap between established history and rapid catch-up is most visible.

International Standards (Swagelok, Parker): Operating on a mature, rigorous standard system. Products are strictly categorized into Low (LL), Medium (L), and High Pressure (S). Their mastery over the "S" series represents the pinnacle of material science and geometric precision.

Domestic Standards (MASTER, etc.): Historically reliant on imports, domestic brands are now rewriting the narrative. While they comfortably match the "L" series (Medium Pressure), the ultra-high-pressure segment remains a challenge. Tolerances and material consistency still have room for refinement compared to Western rigor.

2. Structural Design & Sealing Performance

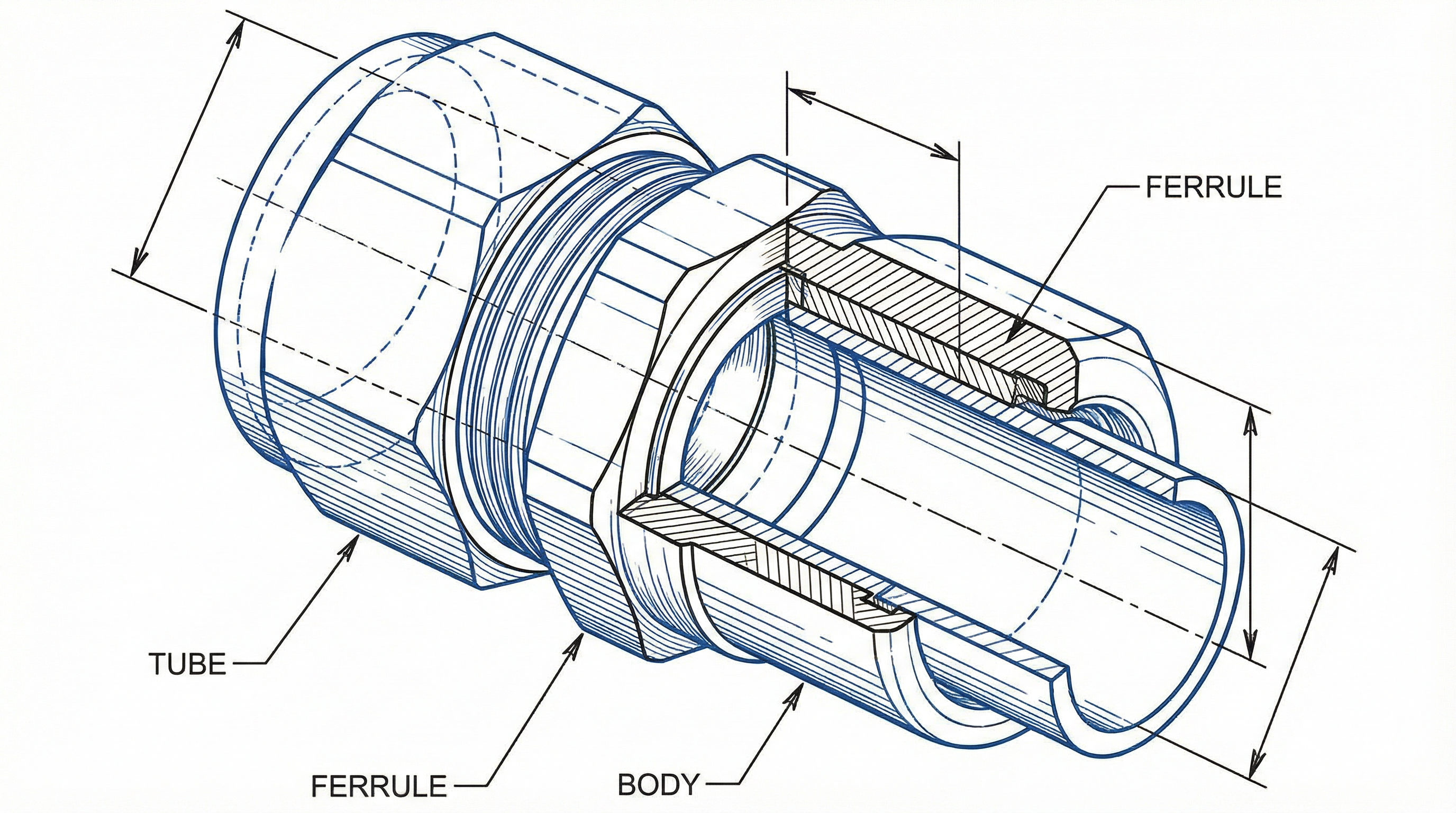

The magic of a ferrule fitting lies in how it grips the tube. This is a battle of geometry and physics between the "perfect seal" and the "cost-effective grip."

International Innovation: Western engineering goes beyond basics. Leaders utilize "Ferrule + Elastic Seal" composite structures. For challenges like Hydrogen embrittlement, specific designs with proprietary heat treatments ensure safety in extreme chemical environments. Domestic Approach: predominantly relying on the classic Double-Ferrule Hinge structure. While effective, it often requires high installation torque. Reusability is a concern; after multiple disassembly cycles, the risk of leakage increases compared to premium foreign counterparts. |

3. Manufacturing Process & Quality

A design is only as good as its production. For giants like Swagelok, the process is scientific. Every step is standardized, and tightening torque is measured by calibrated tools, reducing human variables to near zero.

In contrast, the domestic landscape is fragmented. While top-tier firms are introducing automated CNC lines, many smaller workshops still rely heavily on manual assembly. This reliance on operator skill introduces fluctuation in sealing reliability. The transition to fully automated "Industry 4.0" standards is still underway in China.

4. Market Application & Positioning

Where are these fittings actually used? The market segmentation tells a vivid story of risk tolerance.

The "No-Fail" Zone (Foreign Brands)Aerospace, marine shipbuilding, and high-end hydraulic systems. When a fuel line vibrates at 30,000 feet, the premium paid is an insurance policy against catastrophe.

The Cost-Effective Workhorse (Domestic Brands)Electricity, general mechanical engineering, and construction machinery. For static, medium-pressure lines, domestic fittings offer 90% of the performance for 30% of the price.

5. Price & After-Sales Service

The most tangible differentiator for procurement departments often lies in the balance between budget and agility.

| Feature | Domestic Brands | International Brands |

|---|---|---|

| Price | Affordable (starts ~0.95 RMB) | Premium (+15-20% higher) |

| Response Time | 24-hour response | Up to 72 hours |

| Repair Cycle | 3-5 days | Long cycle (overseas shipping) |

| Customization | Flexible (4-6 weeks) | Heavy surcharges & long lead |

Conclusion

The comparison between domestic and foreign ferrule fittings is no longer a simple story of "Cheap vs. Quality." It is a nuanced landscape of Cost-Benefit Analysis.

Foreign Brands remain the undisputed kings of the high-end, high-risk domains, valued for absolute reliability. Meanwhile, Domestic Brands have conquered the mid-to-low market and are aggressively besieging the high end with agility and service speed. As Chinese manufacturing matures, the line between these two worlds is blurring, offering the global market more choices than ever before.

Contact Us