In the complex landscape of industrial production and scientific research, the purity of a gas is far more than a number on a label. The distinction between "Four Nines" (99.99%) and "Five Nines" (99.999%) represents a fundamental divide in impurity control, application boundaries, and equipment architecture, dictating process stability and product quality.

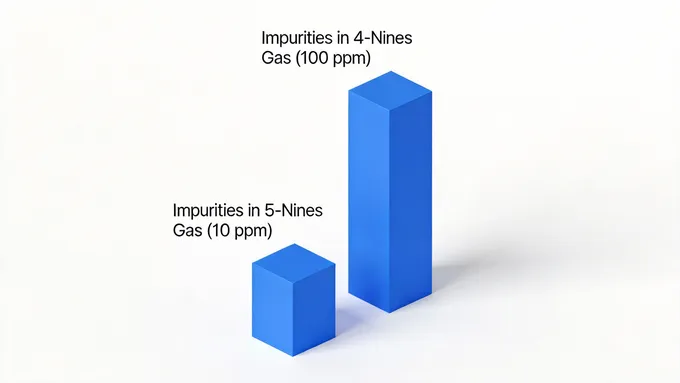

A Difference in Magnitude: Impurity Control

The leap from 4N (99.99%) to 5N (99.999%) is not linear; it is exponential. While "Four Nines" Argon contains 0.01% impurities, "Five Nines" Argon reduces this to 0.001%—a tenfold reduction in contaminants. This seemingly subtle shift has profound implications.

Precision in Practice: Application Scenarios

Where "4 Nines" Shines:

Shielding Gas for Welding: In TIG welding, 4N Argon prevents oxidation of stainless steel, offering a superior cost-benefit ratio.

Laboratory Analysis: For Gas Chromatography (GC), it serves as a reliable carrier gas without interfering with most analyses.

Metal Heat Treatment: In quenching processes, it prevents surface decarburization, meeting general industry standards.

The Realm of "5 Nines":

Advanced Semiconductor Manufacturing: Maintains an ultra-clean environment essential for preventing fatal gate oxide breakdown in wafer lithography.

Quantum Computing: Critical for cooling systems and extending the coherence time of quantum states.

Optical Coating: Ensures film uniformity and prevents cracking by controlling moisture to extreme lows.

The Ripple Effect: Equipment Compatibility & Cost

Upgraded Demands on Equipment:

Storing 5N gas requires BA grade stainless steel cylinders with electropolished inner walls, unlike the standard carbon steel cylinders for 4N gas. Similarly, pressure regulators must be upgraded to EP grade stainless steel with high-performance FFKM seals, a significant step up from standard components.

A Dynamic Cost-Benefit Balance:

The price reflects complexity: a cylinder of 5N Argon can cost 3-4 times more than 4N Argon. This is due to advanced purification processes. However, in sensitive applications like HJT solar cells, the slight cost increase from using 5N Argon is justified by a significant yield increase, demonstrating the strategic value of choosing the right purity.

Conclusion

From a welding workshop to a quantum lab, the upgrade in gas purity mirrors the evolution of industrial technology. Understanding the essential difference between "Four Nines" and "Five Nines" is not just chemistry—it is about finding the strategic equilibrium between cost control and the relentless pursuit of quality. Choose wisely, for purity is power.